Sheet Metal Bending Methods: A Graphical Explanation of Four Bending Techniques!

Bending is a process of folding and bending flat panels, which follows the cutting process in the entire manufacturing chain. The workpiece is placed on a die with a V-shaped opening. A wedge-shaped tool (upper tool) presses the workpiece into the V-shaped opening and bends the sheet to the required angle in this manner.

Most bending parts are made using processes and methods such as free bending, die bending, and edge folding and pressing. The operation follows the same principle: the punch presses the workpiece into the lower die of the die. Therefore, the bending machine that performs the above processes and methods is called a die bending machine.

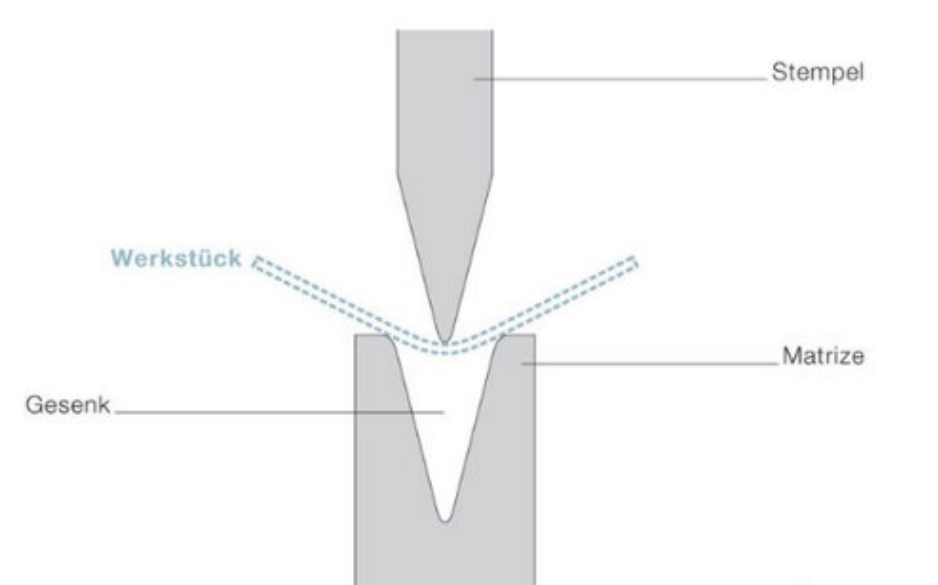

1. **Free Bending**

The punch presses the workpiece into the die without pressing it against the die wall. As the punch descends, the edge of the workpiece bends upwards and forms an angle. The deeper the punch presses the workpiece into the die, the smaller the angle becomes. At this time, there is a gap between the punch and the die.

Free bending is also known as a path-dependent process. Each angle requires a specific path. The machine tool control system calculates the path and the corresponding punch force simultaneously. The path and punch force depend on the mold, material, and product characteristics (angle, length).

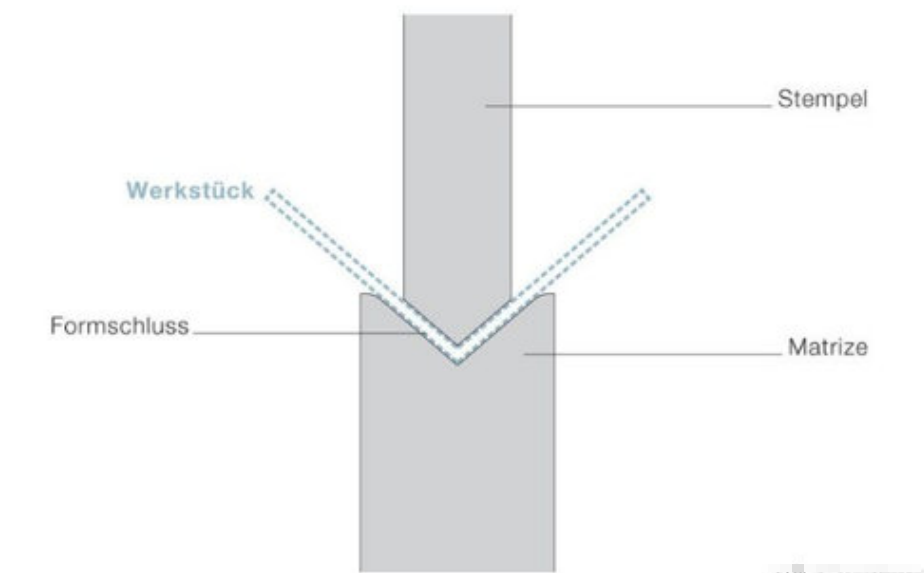

2. **Die Bending**

The punch fully presses the workpiece into the die, leaving no gap between the die, workpiece, and punch. This process is called die closing.

The punch and die must fit together precisely. Therefore, each angle and shape requires the corresponding mold components. Once the workpiece is fully pressed in, the punch cannot continue to move downward. The machine tool control system continues to increase the punch force until it reaches the specified value. The pressure applied to the workpiece increases, thereby presenting the outline of the punch and die. The angle gradually solidifies under high pressure, almost completely eliminating the rebound problem.

3. **Flanging Bending**

The bending arm built into the machine is made of C-shaped profiles, with lower and upper bending molds installed on it. During bending, the C-shaped profile moves up and down or performs a small range of elliptical motion, that is, flipping. The arm bending machine operates semi-automatically, known for its speed and flexibility, even small batch production is completed without inferiority. In addition, through flanging bending technology, it is also possible to use the same mold to achieve efficient bending of various radius sizes on a single part.

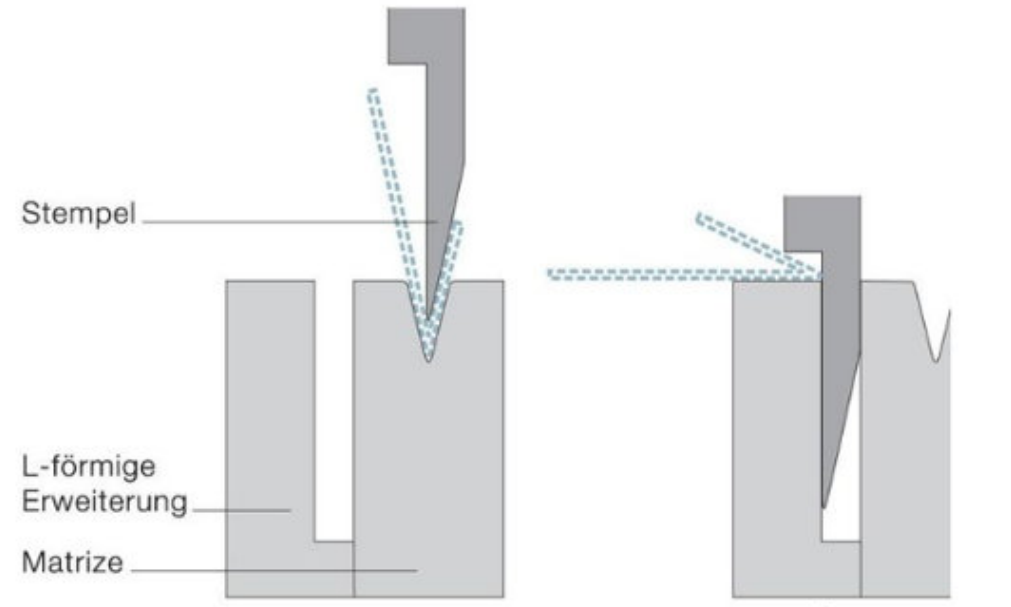

4. **Edge Folding and Pressing**

The edge of the sheet is usually completely bent (such as the edge of a box), and then the edges are parallel to each other. As a result, the finished piece is more stable or forms an edge protection. Subsequently, the edges usually need to be hung with other parts. Edge folding and pressing are completed in two steps: first, the operator pre-bends a 30° angle, and then the workpiece is reinserted and pressed to close the angle. If there is a gap between the edges, it is called folding. In pressing, the bent edges are completely squeezed against each other. Folding is path-dependent, while pressing is force-dependent.

**Industry Applications**

Whether it’s a microwave oven, washing machine, or stove – most household appliances are made up of structures using very thin sheets and a large amount of forming processing, which must withstand many years of use. Therefore, white goods manufacturers need production partners who provide stamping and bending machines to flexibly process sheet metal parts. Since household appliances always have many visible parts, processing without surface damage or indentation is essential. The commonly used galvanized sheet is beneficial to stamping because the zinc layer is pulled to the top of the edge during the stamping process, preventing future corrosion. The washing machine drum in particular requires high-quality welding to prevent damage to clothing.

Laser welding is convincing with its high-quality results.

Switch cabinet housings, plug-ins, and the casings of electrical equipment itself – all of these are made of sheet metal structures. The laser cutting machines, stamping presses, and bending machines can process thin plate parts with many edges, often very complex. The flexible processing methods of Tongkuan machine tools can be used for pressing in components, forming processing, and profile processing. Laser welding technology also saves time and cost for customers in the electronics industry because it achieves high-quality seams, almost without any follow-up work.

Smbctools has a complete and scientific quality management system, and has been recognized in the industry for its integrity, strength, and product quality.

Leave a Reply

Want to join the discussion?Feel free to contribute!