How to calculate press brake working tonnage?

How to Calculate Press Brake Machines Tonnage? For determining the hydraulic bending force or the tonnage of the press brake that is required to bend the sheet metal in a specific thickness you have totally the following TWO methods:

By the press brake tonnage chart

By the bending force calculation formula

Only after the tonnage of the press brake confirmed, then you can spend your time taking other factors (press brakecomponents, toolings, controllers, etc) into consideration before making your decision to purchase the press brake.In this article, we will show you how to determine the required bending force by your sheet metal.

1.Press Brake Tonnage Chart

The following press brake tonnage chart is used by many press brake manufacturers both in China and abroad countries.

We know that many press brake suppliers are using a different chart, but most of them are similar and the final resultwill almost the same. So just take one of them as your reference.

Note: if there are no special requirements for the bending radius, the slot width v should be 8-10 times plate thickness.The tonnage as shown in the above press brake tonnage chart is calculated based on the sheet metal with the tensilestrength ob=450N/mm2 and length L=1m.

Now you have the bending force chart, the question is how to find the press brake tonnage in the above chart?

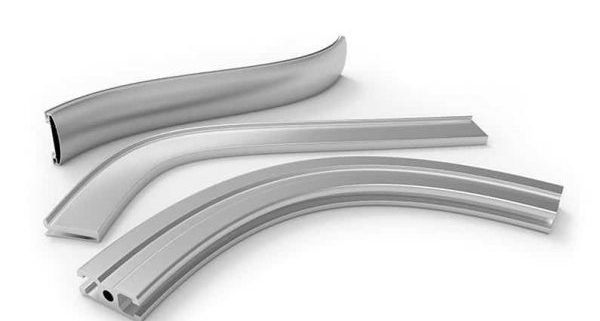

First,you need to know what does “s””V”“B”“R”means in the above chart. Check out the following pictures you will understand what do they mean.

- P= Bending force

- S = Thickness of sheet

- V = Vee opening of the bottom die

- B = Min bending flange

- R = Inner radius

If the thickness of your metal sheet S =4mm, generally the vee opening of the bottom die is 8 times the thickness of the sheet.However, for the thicker plate, the vee opening should be bigger.The following recommend vee opening of the bottom die can be your reference.

| S | 0.5-3mm | 3-8mm | 9-10mm | >12mm |

|---|---|---|---|---|

| V | 6S | 8S | 10S | 12S |

Now we back to the chart, find the S data in the chart which is “4” ,and now we know the “”V” should be 4*8=32.And you can see that the intersection of the row and column where the “s” and v”stay is “330” . The unit of”330”is“KN”.

Now we know that for bending the sheet metal with 4mm thickness and 1m length, the required tonnage is 330KN.lf bend the 4mm sheet in 3 meters, then the tonnage should be 330*3=990KN, which equals to 101 Ton.

Here we come to the conclusion: you should choose at least 100ton press brake. However, we recommend you tochoose the bigger tonnage like 120Ton because if the press brake works in full load for a long time, the service life of the machine will be shortened.

2.Bending Force Calculation Formula

For example:

Plate thickness S=4mm, width L=3m, ob=450N/mm2 Generally slot width V=S*8

Therefore P=650*4*4*3/4*8=975(KN)= 99.5(Ton)

The result is very close to the data in the bending force chart.

As you can see, method #1 to calculate the press brake tonnage is based on the mild steel material.What if the material is stainless steel, aluminum or brass?

lt’ s simple, multiply the results calculated by the above formula by the coefficients in the following table:

| Material | Mild steel | Stainless steel | Aluminum | Brass |

|---|---|---|---|---|

| Coefficients | 1 | 1.6 | 0.65 | 0.5 |

#2.Formula

Another press brake tonnage calculation formula is: P=1.42obS*L/v

P: bending force (KN)

S: plate thickness (mm)

L: plate width(m)

V: bottom die slot width (mm)

ob: tensile strength (Mpa)

For example:

Plate thickness S=4mm, width L=3m, ob=450N/mm2,Generally slot width V=S*8

Therefore P=1.42*450*4*4*3/4*8=958.5(KN)= 96 (Ton) For bending the sheet metal with different materials, the key point is to find out the tensile strength of the specific material, then you will get the required bending force by the above formula.

The tensile strength table below can be the reference:

| Material | Soft(N/mm2) | Hard(N/mm2) |

|---|---|---|

| Lead | 25-40 | — |

[/fusion_table][fusion_text columns=”” column_min_width=”” column_spacing=”” rule_style=”default” rule_size=”” rule_color=”” class=”” id=””]

| Tin | 40-50 | |

| Aluminum | 93 | 1710 |

| Aluminum Alloy Type 4 | 230 | 480 |

| Duralumin | 260 | 480 |

| Zinc | 150 | 250 |

| Copper | 220-280 | 300-400 |

| Brass(70:30) | 330 | 530 |

| Brass(60:40)) | 380 | 490 |

| Phosphor Bronze/Bronze | 400-500 | 500-750 |

| Nickel Silver | 350-450 | 550-700 |

| Cold Rolled Iron | 320-380 | |

| Steel .1% Carbon | 320 | 400 |

| Steel .2% Carbon | 400 | 500 |

| Steel .3% Carbon | 450 | 600 |

| Steel .4% Carbon | 560 | 720 |

| Steel .6% Carbon | 720 | 900 |

| Steel .8% Carbon | 900 | 1100 |

| Steel 1.0% Carbon | 1000 | 1300 |

| Silicon Steel | 550 | 650 |

| Stainless Steel | 650-700 | |

| Nickel | 440-500 | 570-630 |

Ответить

Хотите присоединиться к обсуждению?Не стесняйтесь вносить свой вклад!