How to choose press brake dies(toolings)

The press brake dies(toolings) are very important to the sheet metal producer,they are the key parts for press brake machine,this article briefly introduce how to to choose press brake dies(toolings)

The different dies should be used for fabricating different workpieces. You need to know the fabrication parameters of the press brake machine as well as the die very well, then it is possible for you to choose the right press brake die to match each other.The parameters of press brake including stroke, working ability, daylight (open height),middle plate type.

A.How to choose press brake parameters

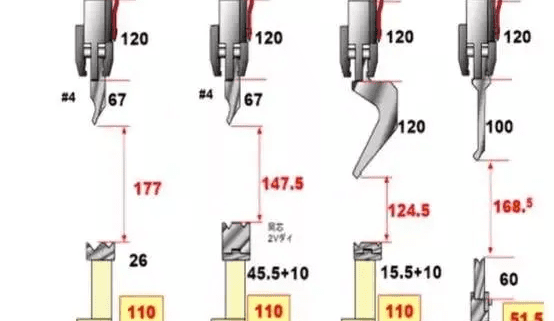

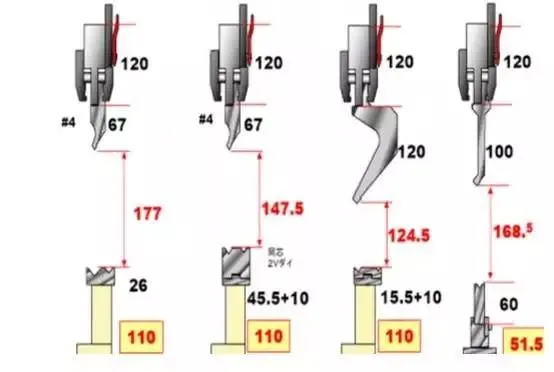

Press brake die height formula

– Stroke (mm)=daylight – middle plate height – upper die height – lower die height -(lowerdie height – 0.5V+t) t = plate thickness (mm)

Given: daylight 370mm, max stroke 100mm

Reach: stroke = 370-120-70-75-(26-0.5*8+t)= (83-t)mm

Note: 0.5V < stroke < max stroke

Please note the lower die base also have many different heights, which is used fordifferent fabrication purpose.So don’t forget this when choosing lower die base.

Different tool & die cluster can obtain different combined height for different fabricationpurposes of parts.

B.How to choose press brake dies parameters

Upper die shank type

Upper die shank has three types to match different middle plate.

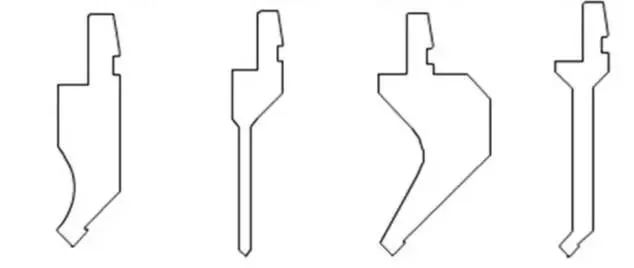

Upper die shape

Common standard upper die:

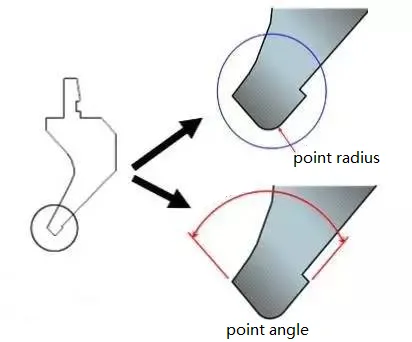

Upper die tip radius & top angle

Common upper die tip radius including:

(1)0.2R (2)0.6R (3)0.8R (4)1.5R (5)3.0R

How to choose proper press brake die tip radius: choose 0.6R for plate thickness

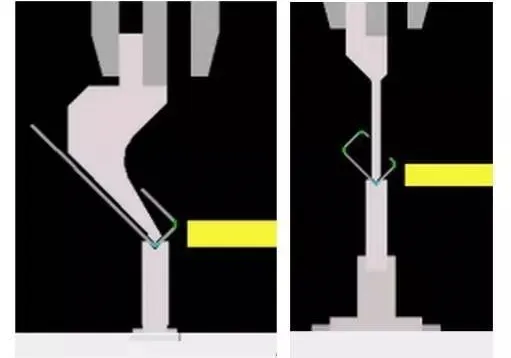

Standard upper die tip angle including: 90°,88°,86°,60°,45°,30°, etc.

The dihedral angle of the die should less than the fabrication angle.

For example, if the workpiece’s bending angle is 90° , you should choose the die with 88° tipangle.

Lower die type

Generally, the lower die has a single V type and double V type, among which it is separatedinto the separated die and full-length die.

The different die is applied to a different fabricating purpose.

However, the single-V die has a much wider application than double-V die, while theseparated die is more widely used than full-length die.

Lower die V width (die opening), V groove angle

V groove choosing & plate thickness (T):

| T | 0.5-2.6 | 3-8 | 9-10 | ≥12 |

|---|---|---|---|---|

| V | 6*T | 8*T | 10*T | 12*T |

The V angle of the lower die is the same as upper die’s angle.

| PLATE THICKNESS | ≤0.6 | 1 | 1.2 | 1.5 | 2 | 2.5 | 3 |

| DIE WIDTH | 4 | 6 | 8 | 10 | 12 | 16 | 18 |

ln order to choose small V die for bending purpose in some special case, the spread ofevery punch should increase 0.2mm

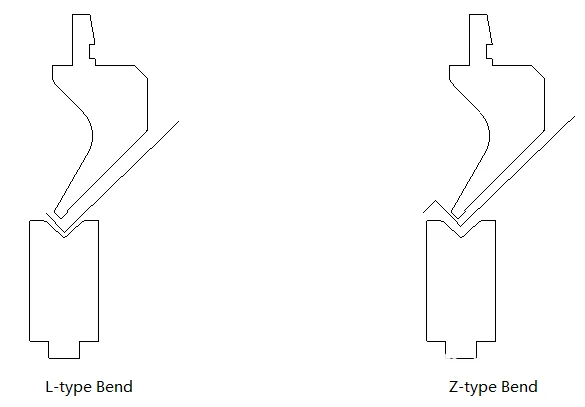

Min bending size

Normally min bending size:

一L-type: slot width/2+ plate thickness

一Z-type: slot width/2 + plate thickness* 2

Reference Value

| L-Type | 4.0 | 4.5 | 5.0 | 6.0 | 8.0 | 10.5 | 12.0 |

| Z-Type | 5.0 | 5.5 | 6.0 | 8.0 | 10.0 | 13.0 | 15.0 |

Leave a Reply

Want to join the discussion?Feel free to contribute!