Competition in the sheet metal processing industry is becoming increasingly fierce. If companies want to remain invincible, they must continue to improve their processing technology. In some bending applications such as precision stainless steel, aluminum alloy, aerospace parts and copper plates, users are no longer satisfied with the functionality of the product, and have higher requirements for its processability and aesthetics. Traditional bending processes are more likely to damage the surface of the work piece. The surface in contact with the mold will form an obvious indentation or scratch. Since the mark cannot be removed, the part will be scrapped. Therefore, users have an increasingly strong demand for no-mark bending.we also call it mark-free bending

The impact of press brake die parameters on bending indentation

- The opening width of V

When coming to bend metal sheets of different thicknesses, the V opening width of lower die is also different.

Under the conditions of the same plate thickness and the same upper die, the larger the size of the V opening, according to the principle of three-force balance, the smaller the pressure between the metal plate and the shoulder of the V opening, the smaller the friction force, and the naturally smaller the indentation depth. Therefore, it is recommended to use a slightly larger V opening lower die.

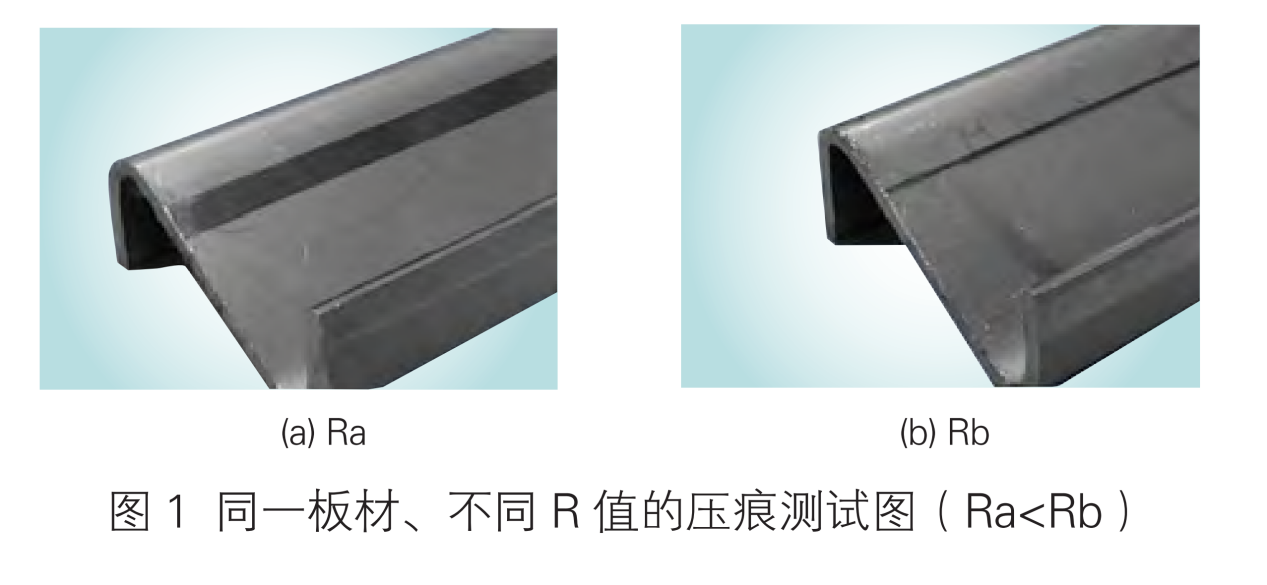

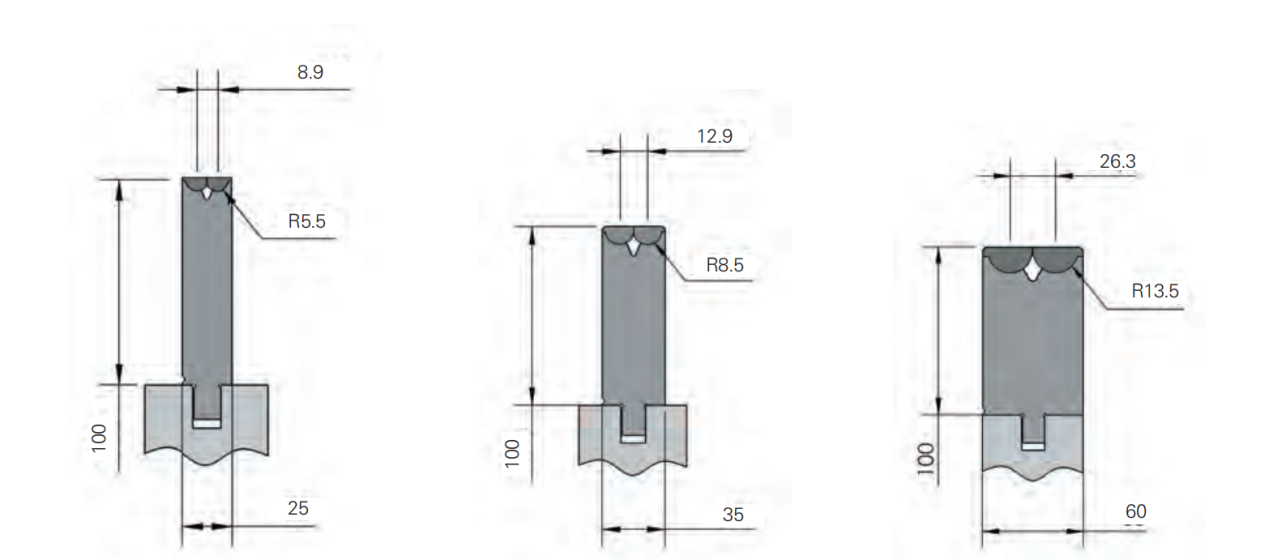

- The R-value of the rounded corner

The R value of the V-shaped shoulder radius is different, and the friction force on the plate during the bending process is different.

The larger R value of the V-opening shoulder, the smaller pressure between the plate and the V-opening shoulder, and the lighter the indentation, and vice versa.

In the figure 1,the WILA tools press Indentation on the same sheet metal but different R value(Ra<Rb),Obviously, the bending indentation of Ra is more significant than Rb.

Therefore, it is recommended to use a lower die with a slightly larger shoulder radius.

The solution for no-mark bending

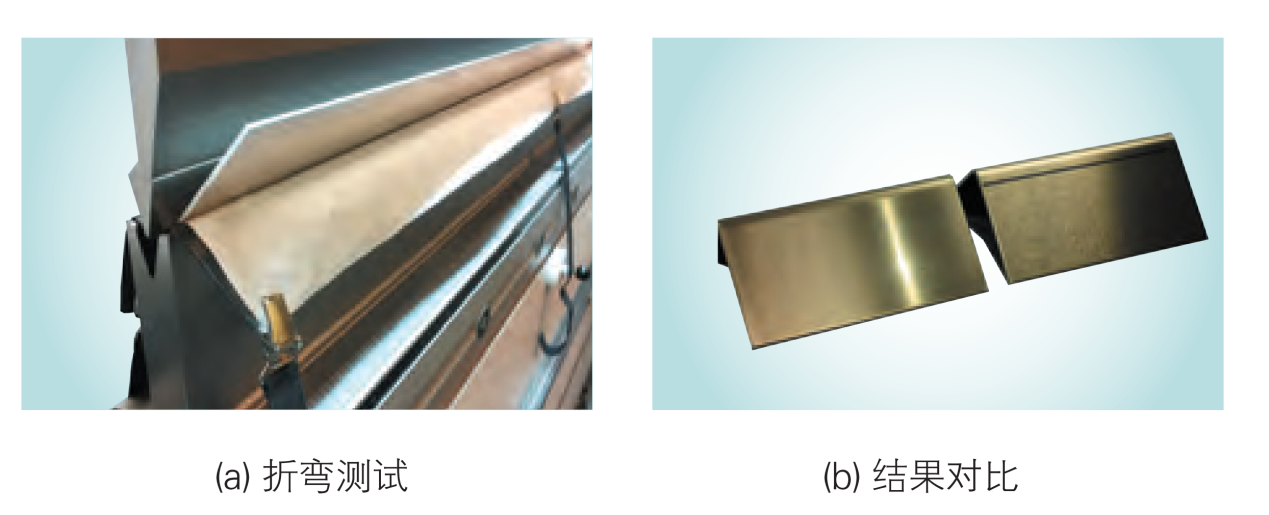

1.Protective cloth or foil

From the perspective of friction, the upper and lower molds can be separated by a foil to avoid direct contact between the molds with the plate, and a non-marking pressing film foil can be used to separate the upper and lower molds. This mainly acts as a buffer between the workpiece and the shoulder of the lower mold, reduces the friction coefficient, and offsets the pressure between the mold and the plate, thereby preventing the workpiece from having indentations when it is bent.

It has the advantages of low cost and easy use. When using it, just put the no-mark pressing film on the lower mold.

Figure 2 The test results show that the use of non-marking pressing film can effectively avoid bending marks.

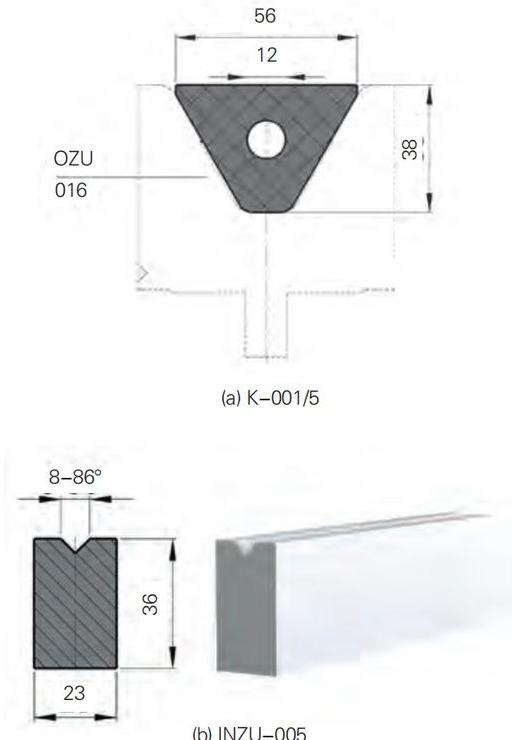

2.Tools with plastic inserts

From the perspective of friction pair, it is possible to consider changing the V-groove shoulder to no-metallic material which is softer than the plate, such as polyurethane, nylon, etc., while ensuring the original required extrusion effect.

high-strength nylon material combinate with an extended mold. It is usually used for bending aluminum plates with a thickness of 0.4~0.5mm in specific occasions, will have a better results.

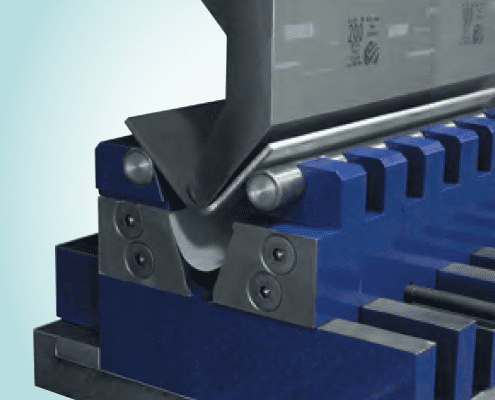

3.Rotabend bottom tools

Rotabend bottom tools helps reduce marking.lts hardened rotor wingsreduce friction.which using rotating supports to enable high quality sheet metal forming,we called Unmarked bending of tension spring in China

Thanks to the tightest tolerances, CNC deep hardening of the contact surfaces and the rotatable V-neck, it is easy to produce parts with short flanges using rotary wing dies to maximally reduce the marks on the work piece when bending the sheet metals.

The advantage of Rotabend bottom tools:

(1) Holes and grooves are produced without deformation in the area close to the bend centerline.

(2) Indentations on the surface of the work piece are reduced when it is bent.

(3) Very small bend fillets can be obtained.

(4) The rotor and contact surfaces are hardened to ensure a long service life and precision.

(5) The rotor is easy to disassemble and assemble, making it easy to clean and maintain.

(6) The strict tolerance requirements during mold processing ensure the ultimate precision during bending operations.

(7) The compact mold size design ensures maximum bending freedom.

(8) The same mold can be used to bend plates of various thicknesses.

(9) It can be used in combination with certain customized lower molds to perform 90° bends

4.Ball mark free bending mold

Based on the principle of reducing the friction coefficient of the friction pair between the sheet and the V groove, the sliding friction pair of the sheet and the shoulder of the V groove can be transformed into a rolling friction pair, thereby greatly reducing the friction force to which the sheet is subjected.This can effectively avoid bending indentation.