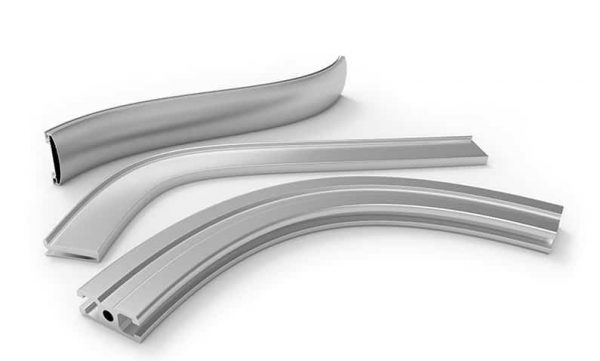

the Best 3 Types Aluminum Alloys for Bending

Before discussing aluminum alloys, we should cover some background about the factors that affect their bendability. As you can imagine, products like aluminum foil, gutters, traffic signs, and automotive body parts, which are all made from aluminum alloys, have different bendability.

Three factors control the bendability of the various alloys in these products:

- The formability of the aluminum alloy

- Thickness and bend radius

- Percent elongation

Let’s have a deeper look at these factors!

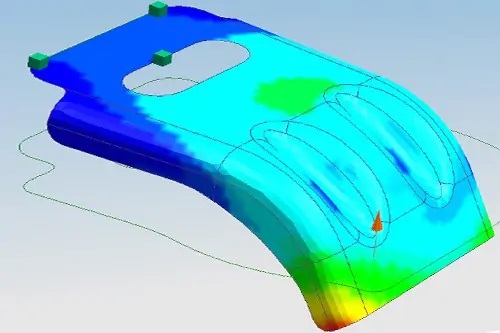

1st Factor – Formability

Formability is the ability of a given material to experience permanent deformation without the forming process cracking or tearing it. Permanent deformation is also known as plastic deformation in the materials science world.

Generally speaking, formability is a relative term and not a specific value. For example, the applied force necessary to shape a product depends on more than just the strength and ductility of a material. It also depends on factors such as the shape of the part and the thickness of the starting material.

In other words, we can measure the forming force to produce a specific part from a particular starting material. However, changing the shape of the part or the physical properties of the starting material will change the amount of force that needs to be applied.

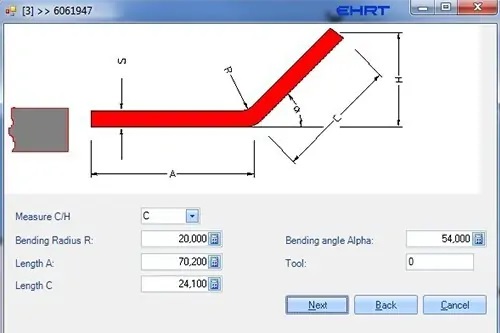

2nd Factor – Thickness and Bend Radius

If you’ve handled regular aluminum foil, you’ll know that it is effortless to bend. However, if you had to bend a sheet of aluminum that was one-thousand times thicker than aluminum foil, it would be much harder! That is because the thicker a material is, the more difficult it is to bend.

You can also bend an aluminum gutter with your bare hands. But if you try to bend it to a tight angle without breaking it, you will have a hard time! Bending metal to a small bend radius has the potential to cause tearing or cracking.

The Fabricator offers certain key tables and general rules which are helpful for understanding the limits to bendability for specific aluminum alloys. You can use these to determine the minimum allowable bend radius for particular thicknesses of aluminum sheet.

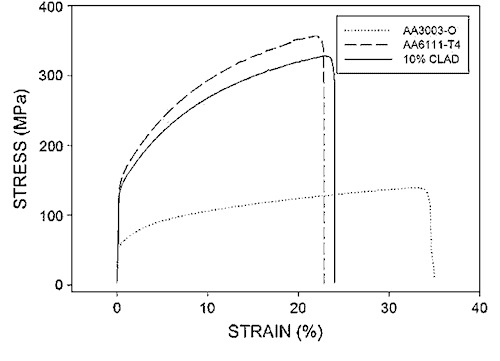

3rd Factor – Percent Elongation

Percent elongation represents the ability of the material to be plastically deformed under tension. It is also known as plastic strain or stain applied beyond the yield strength limit of a material.

The more ductile aluminum alloys can experience more significant plastic deformation with small increases in applied stress. This results in better overall aluminum bendability.

Like the other properties, the percent elongation varies for each alloy. Take a look at the stress-strain curve above. You’ll see that annealed aluminum alloy 3003 (shown as AA3003-O) has a very high percent elongation (strain %) of roughly 35%. It has very high bendability relative to other alloys.

3 of the Best Aluminum Alloys for Bending

Numerous metal alloying agents can be combined with aluminum to produce different aluminum alloys. The system for naming them uses four digits, with the first digit representing their chemical composition. We explain this in our article on aluminum alloy designations and tempers.

Generally speaking, aluminum alloys from the 1XXX, 3XXX, and 5XXX series demonstrate better bendability than other aluminum alloys. Some 6XXX series alloys are fairly bendable as well.

However, the different properties offered by each may make some more desirable than others. For example, 1XXX series aluminum generally has poor mechanical properties and is not suited to structural applications.

Now let’s discuss which alloys offer the best bendability and when you should use them.

#1 – Aluminum Alloy 3003

This alloy is primarily alloyed with manganese and is one of the most commonly used aluminum alloys for bending applications. It has excellent formability properties and does not require heat to be bent or molded.

Companies often make gutters, roofing, siding, chemical equipment, and storage tanks from 3003 aluminum.

#2 – Aluminum Alloy 5052

With magnesium as the primary alloying element, AA5052 demonstrates moderate-to-high strength characteristics. At the same time, it retains good bendability, and designers can use it for more intensive applications than AA3003. The corrosion resistance of this alloy is also excellent against seawater, meaning it is excellent for applications in marine equipment.

Manufacturers often produce hydraulic tubes, traffic and hardware signs, medical equipment, marine equipment, and electronics (chassis and enclosures).

#3 – Aluminum Alloy 6061

You will find this is an extremely common alloy in your day-to-day life. Even though it is not as bendable or formable as the two alloys above, it is the strongest among all three. It has magnesium and silicon as alloying elements, and you can further enhance its strength with heat treatment.

Alloy 6061 is widely referred to as “structural aluminum” because it is so commonly used in structural (construction) applications. Nevertheless, due to its outstanding properties, it is also used in food and beverage containers, ladders, aircraft and automotive parts, scuba tanks, bicycle frames, and more.

Why Are These 3 Alloys Important?

Despite their different properties, these alloys are excellent examples of bendability in aluminum alloys. They demonstrate that even though some aluminum alloys feature better formability and percent elongation for a given bend radius and thickness, they each serve a unique purpose and a wide variety of applications.

Even with slightly lower bendability, the strength of alloy 6061 makes it one of the most widely used aluminum alloys. In the same way, alloy 3003 has multiple uses in applications that require superior bendability. Meanwhile, alloy 5052 is commonly used thanks to its balance in terms of bendability and strength.

Explanation of aluminum plate grade

1000 series representative

1050, 1060, 1070, 1000 series aluminum plate is also called pure aluminum plate.Among all series, 1000 series belongs to the series with the most aluminum content.The purity can reach more than 99.00%.

Because it does not contain other technical elements, the production process is relatively single and the price is relatively cheap.It is the most commonly used series in conventional industry at present.At present, most of the products in circulation in the market are 1050 and 1060 series.

The minimum aluminum content of the 1000 series aluminum plate is determined according to the last two Arabic numerals. For example, the last two Arabic numerals of the 1050 series are 50.According to the international brand naming principle, the aluminum content must reach 99.5%, and the above is regarded as qualified products.China’s aluminum alloy technical standard (GB / t3880-2006) also clearly stipulates that the aluminum content of 1050 must reach 99.5%.Similarly, the aluminum content of 1060 series aluminum plates must reach more than 99.6%.

1000 series typical brand and application:Pure aluminum plate 1060 is mainly used in occasions requiring high corrosion resistance and formability, but for parts with low strength, such as chemical equipment, marine equipment, railway oil tank car, conductor materials, instrument materials, welding rods, etc.

2000 series aluminum plate representative

2A16 (LY16), 2A06 (LY6) and 2000 series aluminum plates are characterized by high hardness, of which the original content of copper is the highest, about 3-5%.

2A12 aluminum alloy is a kind of high strength hard aluminum, which can be strengthened by heat treatment; 2A12 aluminum alloy has good spot weldability and tends to form intergranular cracks when gas welding and argon arc welding are used;

2A12 aluminum alloy has good machinability after cold work hardening.

The corrosion resistance is not high. Anodizing and painting methods or aluminum coating on the surface are often used to improve corrosion resistance.

2000 series aluminum plate belongs to aviation aluminum material, which is not often used in conventional industry at present.

At present, there are few manufacturers producing 2000 series aluminum plates in China.The quality cannot be compared with that of foreign countries.

At present, imported aluminum plates are mainly provided by Korean and German manufacturers.With the development of China’s aerospace industry, the production technology of 2000 series aluminum plate will be further improved.

3000 series aluminum plate representative

3000 series aluminum plates are mainly represented by 30033003 and 3A21. It can also be called antirust aluminum plate.The production process of 3000 series aluminum plate in China is excellent. 3000 series aluminum plate is mainly composed of manganese.The content is between 1.0-1.5. It is a series with good antirust function.It is commonly used in humid environments such as air conditioner, refrigerator and underbody. The price is higher than 1000 series. It is a more commonly used alloy series.

3000 series typical grade and its application:

3003 aluminum is mainly used for processing parts requiring good molding performance, high corrosion resistance, or good weldability, or workpieces requiring higher strength than 1000 series alloy, such as tanks and tanks for transporting liquid, pressure tanks, storage devices, heat exchangers, chemical equipment, aircraft fuel tanks, oil duct, reflective plates, kitchen equipment, washing machine cylinder block, rivet, welding wire.

3004 aluminum requires higher parts than 3003 alloy, chemical product production and storage devices, sheet processing parts, building baffles, cable ducts, sewers and various lamp parts.

4000 series aluminum plate representative

The 4000 series aluminum plate represents the 4a014000 series aluminum plate, which belongs to the series with high silicon content.

Generally, the silicon content is between 45-6.0%.It belongs to building materials, mechanical parts, forging materials and welding materials; Low melting point and good corrosion resistance.Product features: heat resistance and wear resistance.

5000 series representative

The 5000 series represents 5052, 5005, 5083 and 5A05 series.

5000 series aluminum plate belongs to the commonly used alloy aluminum plate series.The main element is magnesium, and the magnesium content is between 3-5%. It can also be called aluminum magnesium alloy.The main features are low density, high tensile strength and high elongation.

Under the same area, the weight of aluminum-magnesium alloy is lower than that of other series, so it is often used in aviation, such as aircraft fuel tank.

It is also widely used in conventional industry. The processing technology is continuous casting and rolling, which belongs to the hot-rolled aluminum plate series, so it can do deep oxidation processing.

In China, the 5000 series aluminum plate is one of the more mature aluminum plate series.

5000 Series typical grade and its application:

5052 aluminum has good forming and processing performance, corrosion resistance, weldability, fatigue strength and medium static strength. It is used to manufacture aircraft fuel tank, oil pipe, sheet metal parts, instruments, street lamp supports, rivets, wires, etc.

6000 series representative

6061 mainly contains magnesium and silicon, so it integrates the advantages of 4000 series and 5000 series.

6061 is a cold-treated aluminum forging product, which is suitable for applications requiring high corrosion resistance and oxidation resistance.

Good usability, excellent interface characteristics, easy coating and good processability.

It can be used for low-pressure weapons and aircraft joints.

General features of 6061: excellent interface features, easy coating, high strength, good usability and corrosion resistance.

Typical uses of 6061 aluminum: aircraft parts, camera parts, couplers, ship accessories and hardware, electronic accessories and connectors, decorative or various hardware, hinge head, magnetic head, brake piston, hydraulic piston, electrical accessories, valves and valve parts.

7000 series representative

7075 mainly contains zinc. It also belongs to Aviation series. It is aluminum magnesium zinc copper alloy, heat treatable alloy, superhard aluminum alloy and has good wear resistance.

7075 aluminum plate is stress relieved and will not deform and warp after processing.

All super large and super thick 7075 aluminum plates are detected by ultrasonic, which can ensure that there are no sand holes and impurities.

7075 aluminum plate has high thermal conductivity, which can shorten the forming time and improve the work efficiency.

7075 is mainly characterized by hardness.

7075 is a high hardness and high strength aluminum alloy, which is commonly used in the manufacture of aircraft structure and futures.

It requires the manufacture of high stress structural parts and molds with high strength and strong magic corrosion resistance.

At present, it basically depends on imports, and China’s production technology needs to be improved.

8000 Series

The more commonly used 8011 belongs to other series.

In my memory, it is an aluminum plate whose main function is to make a bottle cap. It is also used in radiators. Most applications are aluminum foil, which is not commonly used.

Leave a Reply

Want to join the discussion?Feel free to contribute!