6000+

square meters PLANT AREA

100+

Skilled Workers

200+

Customers

About Us

Who We Are

SMBC press brake tools belong to Ma’anshan sparkparts machinery technology co. ltd. located in the Bowang industrial park , Ma’anshan city, Anhui province,China. With superior geographic position and convenient traffic.

As we run in precision machinery parts field for more than 20 years, Now our industry developing include SMBC press bake tooling, SPARK precision industrial blades and gas spring and pneumatic components in China.

Our Partners

why choose SMBC Tools?

For over 30 years, SMBC has delivered the finest PRESSS BRAKE TOOLINGS to our customers. These toolings are manufactured under strict quality control based upon years of studies and accumulated knowledge of the customers’ needs. Due to this,SMBC stands high in the sheet metal fabrication field of not only:China: , but also all over the world

Latest News & Blogs

The Ultimate Guide to Press Brake Tooling Types

Introduction When purchasing or using a press brake, you may often encounter the question: “Which tool should I use to

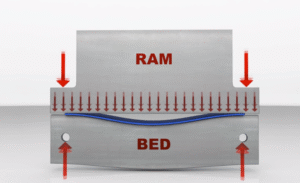

What Is Press Brake Crowning and 2 Types of It

What Is Press Brake Crowning To guarantee accurate, repeatable forming results, it’s essential to compensate for the deflection that inherently

The Ultimate Guide to Press Brake Tooling

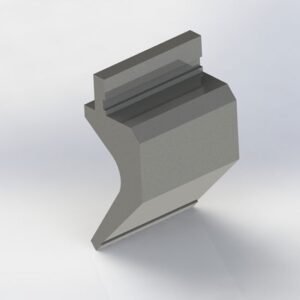

A press brake tool is a machine tool used in metal forming to bend and shape metal sheets. These machines

Sheet Metal Bending Methods: A Graphical Explanation of Four Bending Techniques!

Bending is a process of folding and bending flat panels, which follows the cutting process in the entire manufacturing chain.

Beyond the traditional bending process and achieve 4 solutions for No-mark bending

Competition in the sheet metal processing industry is becoming increasingly fierce. If companies want to remain invincible, they must continue

Sheet Metal Bending: An Engineer’s Manual

1、Common Bending Dies The common bending dies are shown in the figure below. To extend the life of the dies,

![H659dc09099b8401b96f0357d8f461e2ef[1] Amada Press Brake Toolings](https://www.smbctools.com/wp-content/uploads/2020/03/H659dc09099b8401b96f0357d8f461e2ef1-300x300.jpg)

![China-standard-press-brake-tools[1] China Standard Press Brake Tools](https://www.smbctools.com/wp-content/uploads/2020/03/China-standard-press-brake-tools1-300x300.png)

![press-brake-crowning-table[1] Crowning Table](https://www.smbctools.com/wp-content/uploads/2020/03/press-brake-crowning-table1-300x300.jpg)

![crop-shear-curved-knife[1] Cut-to-Length Lines and Guillotine Shears](https://www.smbctools.com/wp-content/uploads/2020/03/crop-shear-curved-knife1-300x300.jpg)

![fast-clamp1-450x450-1[1] Fast Clamp](https://www.smbctools.com/wp-content/uploads/2020/03/fast-clamp1-450x450-11-300x300.jpg)

![no-marking-bend[1] No-Marking Bend](https://www.smbctools.com/wp-content/uploads/2020/03/no-marking-bend1-300x300.jpg)

![ROTARY-SLITTER-KNIVES-450x360-1[1] Rotary Slitter Knives](https://www.smbctools.com/wp-content/uploads/2020/03/ROTARY-SLITTER-KNIVES-450x360-11-300x300.png)